Scale-up Interview: Recycleye

Recycleye is automating waste management by leveraging artificial vision and robotics, increasing visibility and efficiency in recycling.

How would you describe your business idea to a potential investor (who is not an expert in your particular profession)?

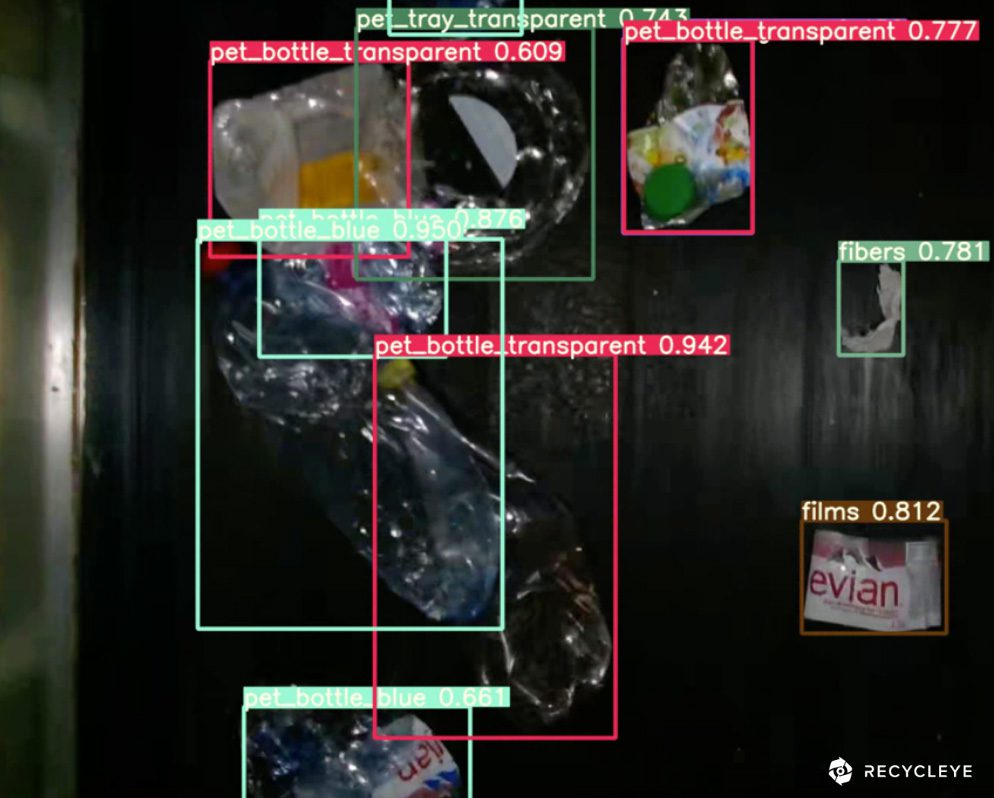

Today, waste is sorted in recycling facilities by traditional analogue machinery and manual pickers. Recycleye provides solutions to automate this process, increasing efficiency and visibility. Recycleye Vision is an AI-powered computer vision system, which leverages a low-cost camera and machine learning algorithms to detect individual items on co-mingled waste streams to a material an object level. For example, it can detect a PET bottle based purely on visual aspects. This system can be used in complement with Recycleye Robotics, an intelligent robotic picker that physically separates the waste.

Recycleye Robotics

What problem do you want to solve, what is your goal?

To date, recycling facilities have faced high contamination in their removal chains which means valuable recyclates are downcycled, reducing the quality and quantity of materials being recovered. The economic inefficiency of manual picking has obstructed facilities from achieving the purity of waste streams required to align with policy and legislation. Recycleye aims to automate the waste sorting process, decreasing reliance on manual picking and thus enabling MRFs to meet purity regulations. This also increases the profit MRFs make from their waste, by aggregating valuable materials. Furthermore, there is a lack of visibility in removal chains, once something is disposed of it is impossible to track, so Recycleye’s dashboard of data insights provides plant managers with traceability of their waste composition, informing strategic decisions.

How did you come up with your idea/concept?

Whilst researching for his PhD at Imperial College, our CEO found that the impact of recycling facilities on a country’s recycling rate has been hindered by complex and expensive waste sorting infrastructure. Particularly, the industry’s reliance on manual pickers to separate items has resulted in lower purity of waste streams. Inspired by developments in AI and robotics technology, in 2019, Recycleye began a mission to prove that “waste doesn’t exist, just materials in the wrong place.” The first prototype of our solution was developed by our co-founders, Victor and Peter, on a treadmill in their garage, with waste collected from the street!

What is your business model?

Recycleye is offering a leasing model for Recycleye Vision and Robotics, enabling facilities to invest in automated solutions with minimal risk and perpetual warranty. This aligns with the low-margin nature of the waste management industry, and reflects the innovative solutions, which are not yet familiar to industry players.

Where can your scale-up be used?

Recycleye works with material recovery facilities (MRFs), on their quality control and assessment lines, to congregate data about the composition outputted to reprocessors. This allows the facilities to make strategic decisions about their operations, based on data-driven actionable insights. Recycleye Robotics automates the differentiation of the waste streams, reducing the need for manual pickers. Recycleye’s solutions can be retrofitted to existing machinery in MRFs, avoiding costly renovations and allowing digitisation of existing MRFs.

Recycleye Robotics

Recycleye Vision

What other benefits does it offer and why is it worth to invest?

Recycleye Vision also allows recycling facilities to anticipate dangers, such as batteries which could cause fires in the plants, consequently facilitating actions to obstruct realisation of these dangers. Also, the purity level which Recycleye Robotics sorts to, along with the visibility of this purity through Recycleye Vision, restructures the business model between MRFs and reprocessors. Recycling facilities will be able to quote exact granularity percentages of bails, or tailor to specific requests from reprocessors, fostering a new pricing model. In addition, Recycleye Vision and Robotics can differentiate to categories such as food-grade vs non-food grade plastics, or packaging vs non-packaging, allowing higher value recyclates to be aggregated and sold for higher prices. Therefore, Recycleye is commoditising waste, driving value and profitable in the waste management industry, which previously relied on analogue and inefficient processes.

Why did you decide to apply to Scaleup4Europe?

Recycleye has strong foundations in the British and French waste management markets, yet we are looking to expand our knowledge and partnerships across the rest of Europe. Through the ScaleUp4Europe programme, we see an opportunity receive guidance on how our technology can be refined to align with differing national markets, as well as introductions to new European partners. Specifically, Germany recycles more than twice the amount of municipal solid waste than any other European nation, whilst simultaneously following the EU’s strictest policy regulations with a recycling rate target of 65% by 2020, suggesting there is a need for automation to ensure targets are met efficiently.

Get more information about Recycleye on their website or connect with the team on LinkedIn or Twitter.

Recycleye is part of the

Scaleup4Europe Smart Region Lab.

You want to join one of the four Scaleup4Europe Labs as well?

Get more information and apply at scaleup4.eu.